Our Commitment to quality

- Offering exceptional products and services and striving to exceed the requirements and expectations of our customers.

- Providing employee education and training that optimizes performance in the quality and delivery of our products.

- Fostering an atmosphere of continuous improvement and problem-solving.

- Empowering employees so that they can help improve the processes and systems that affect their work.

- Developing relationships with our suppliers that emphasize continuous improvement in product quality, service, and support.

- Providing an environment that supports teamwork.

- Maintaining a formal quality management system that meets all ISO9001:2015 and AS9100D standards and continuously improving the effectiveness of the quality management system.

- Establishing clear communication channels to our customers, employees, and suppliers.

CERTIFICATIONS

Usher is certified by Perry Johnson Registrars and holds registrations in AS9100 Revision D and ISO 9001:2015.

CERTIFICATE OF REGISTRATION

QUALITY MANUAL

APPENDIX

Quality Control

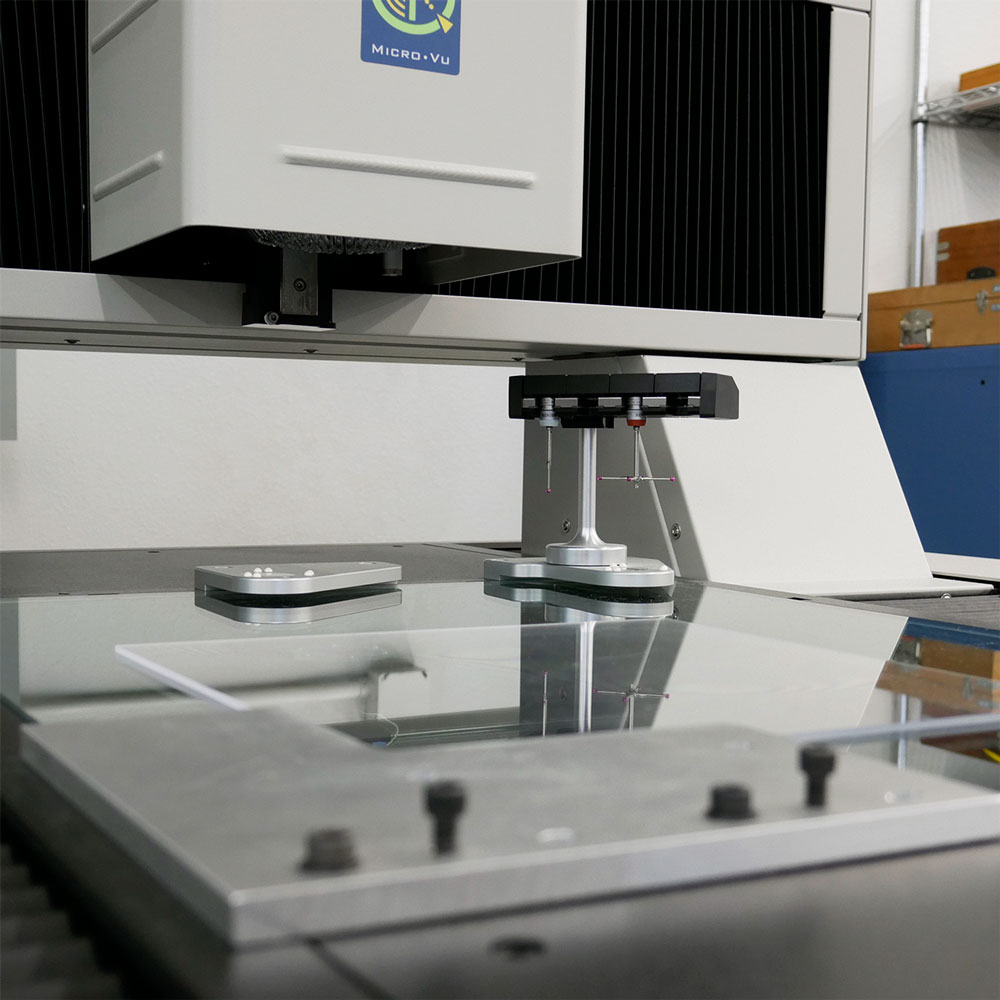

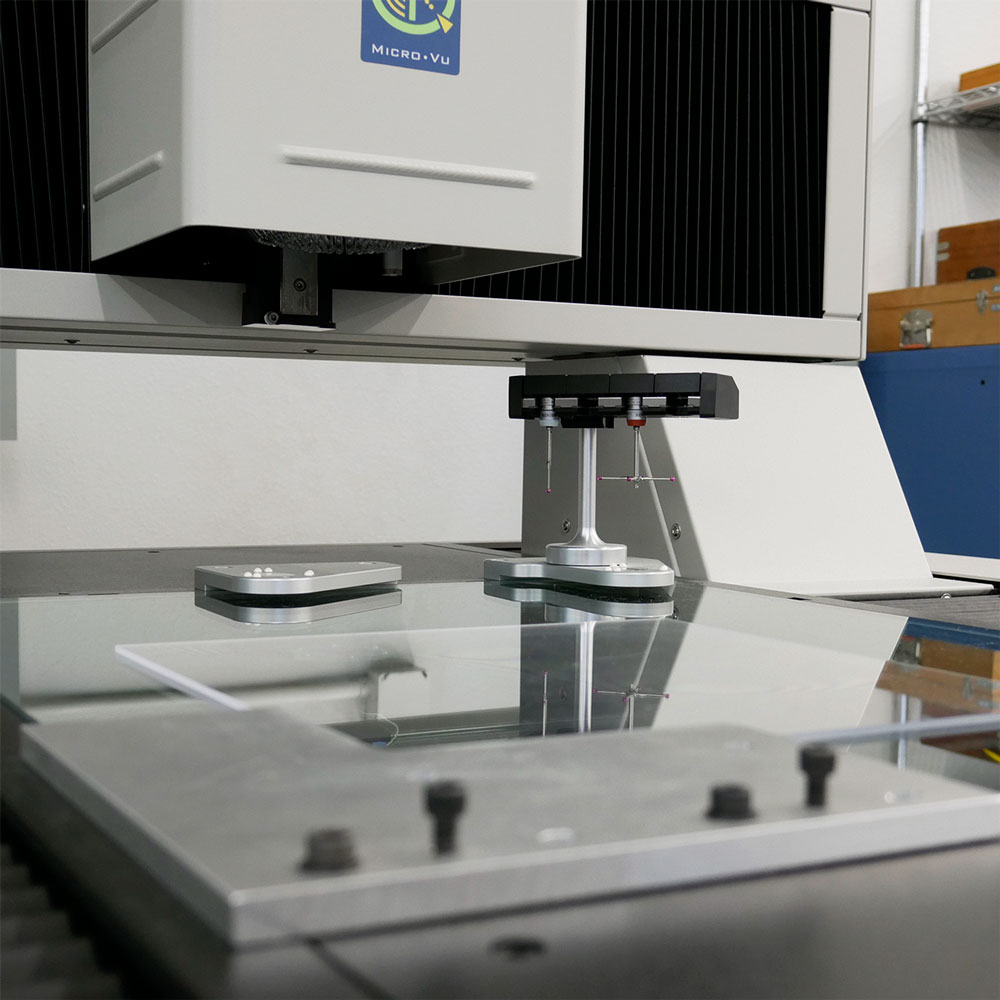

Our Brown & Sharpe Global Image 7.10.7 and Global Advantage 575 CMM’s with PCDMIS software, allows us to inspect the most complicated of parts with ease. With additional inspection software we can manage our Technical Data Packages (TDP) seamlessly and with a level of detail to efficiently create downstream artifacts for manufacturing and quality assurance.

These include First Articles and PPAP’s, Inspection Plans, Manufacturing Process Plans, and Producibility Analysis. Other metrology devices include optical comparators, lab grade surface plates, micrometers of all type, air gaging, and a full complement of thread and hole gaging to name just a few. All measuring devices are tracked utilizing calibration software and each individual gage can be traced to a particular part.

Aerospace

We have assembled a world-class staff of machinists, welders, and engineering professionals with extensive experience in producing precision machined components, fabrications, and assemblies. With a quality management system certified to ISO 9001:2015 and AS9100 Rev D, companies like Rockwell Collins, Northrup Grumman, and Triumph Aerostructures have come to depend on Usher for their machining and assembly needs.

Automotive

At Usher Manufacturing, we collaborate with our customers to provide custom solutions to their automotive production challenges. Our quality assurance team can prepare the required level of PPAP for newly engineered automotive products, ensuring they meet the highest industry standards.

Commercial

Customers like Climax Portable Machining and Welding Systems consider Usher their number one supplier for precision and robust machined components and know that the product will be delivered on time at the level of quality they require.

Medical

Usher aligns itself with companies seeking compliant, cost-effective, domestic medical device manufacturing and can provide you with the same level of expertise that companies such as Spinal Modulation and Engle Dental Systems have come to count on.

Frequently Asked Questions

What is USHER and what is their expertise?

USHER is a manufacturing company that specializes in performance-based manufacturing. They have 49+ years of experience and bring consistency and outstanding performance to all their customers.

What are the services offered by USHER?

USHER offers various services, including assembly, CNC machining, hydroforming, laser cutting, and welding.

What is assembly, and how does USHER help with it?

Assembly involves joining different parts to make a final product. USHER can help with riveting, hardware insertion, mechanical assembly, and final testing of the assembly to ensure that all customer requirements are met.

What is CNC machining, and what are USHER's capabilities in this field?

CNC machining is a process of using computer-controlled tools to produce complex parts. USHER has CNC lathe capabilities, including large through-spindle capacities and live tooling. With these capabilities, they can provide complete parts without the need for secondary operations.

What is hydroforming, and how does USHER use this process?

Hydroforming is a process of shaping metal by using high-pressure hydraulic fluid. USHER uses a rubber diaphragm as the male mating half and can produce a diverse range of shapes while keeping costs low.

What are USHER's welding capabilities?

USHER has exceptional welding capabilities, particularly in thin aluminum welding. As a manufacturer of “certified aircraft” parts, they understand the importance of meeting strict welding specifications.

Why Choose US

Satisfaction Guarantee

A One-Stop Shop

Free Consultation

Request a Quote

Phone: (503) 992-0015

Fax: (503) 992-0012

Email: [email protected]

Address: 3863 24th Ave Forest Grove, Oregon 97116